+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In today's fast-paced business environment, efficiency is key. A Vertical Lift Carousel can significantly enhance storage and retrieval processes. According to a report by the Material Handling Institute, using automated solutions like carousels can improve inventory accuracy by 30%. This statistic underscores the importance of selecting the right carousel for your unique needs.

Choosing the best Vertical Lift Carousel involves several factors. Consider your specific storage requirements, the volume of items, and the physical space available. Many businesses overlook these crucial details, which can lead to inadequate solutions. For instance, a poorly sized carousel may slow down operations instead of streamlining them.

Additionally, the initial cost often clouds judgment. However, investments in quality carousels generally yield long-term savings through increased productivity. Reflecting on your organization's operational needs will lead to more effective decisions. Balancing cost with functionality is vital in making the right choice. A successful implementation can redefine workflow efficiency, making it an essential investment for any forward-thinking business.

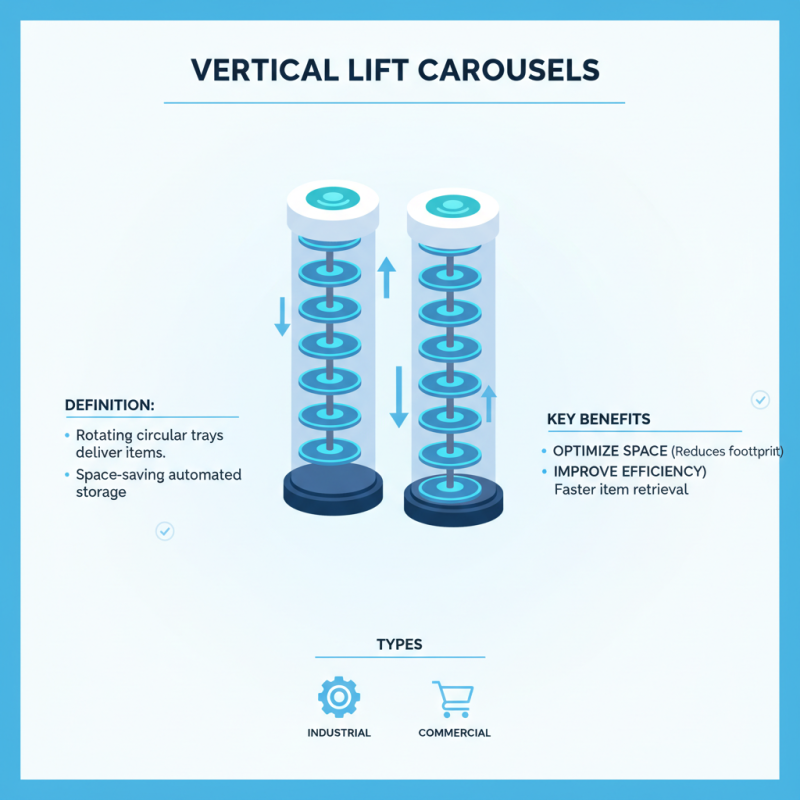

Vertical lift carousels are innovative storage solutions used in various industries. They optimize space and improve efficiency. Understanding their definition and types can help businesses make informed choices. A vertical lift carousel consists of a system of circular trays that rotate to deliver items to an operator. They save floor space and enhance accessibility to stored goods.

There are several types of vertical lift carousels. Some focus on high-density storage, while others emphasize speed and retrieval time. This variety allows businesses to select a model that aligns with their specific needs. For instance, some units cater to smaller items, while others handle bulkier materials. Assessing the layout of your facility is crucial.

Tip: Consider the height of your storage area. This can impact the type of carousel you choose.

Also, think about the types of goods you need to store. Different models are designed for different products. Not every carousel works for every item. It’s essential to identify where your current system falls short.

Tip: Evaluate your current storage process. Are there inefficiencies you can spot? Recognizing these can help you choose the best carousel for your operations.

When choosing a vertical lift carousel, several key factors come into play. The capacity is essential. Determine the weight and volume of your inventory. A carousel that can't handle your loads may slow operations significantly. Be mindful of the dimensions as well. You need ample space for installation and operation while ensuring ease of access.

Consider the technology involved. Automated systems can enhance efficiency but may have a steeper learning curve. Assess the user interface too. Is it intuitive? Can your staff adapt quickly? You want a system that doesn’t disrupt workflow. After all, complicated systems can lead to frustration and delays.

Maintenance requirements also deserve attention. Some models might require frequent servicing, while others are designed for low upkeep. This can affect long-term costs. Reflect on your team’s expertise in addressing technical issues. Not every business has the resources for regular troubleshooting. Evaluate your options thoroughly to find the right fit for your needs.

When selecting a vertical lift carousel, load capacity stands out as a crucial factor. Understanding the weight capacity helps in optimizing storage solutions. Each business has unique needs. Consider the average weight of the items you will store. If items vary widely, ensure the carousel can handle the heaviest ones. This clarity can save headaches later.

Efficiency metrics are equally important, impacting both productivity and costs. Look at the speed of the carousel. A faster unit can improve workflow, but it might come at a higher cost. Think about how often your operations will use it. Over time, energy costs add up. Can you balance initial investment with long-term savings?

Each business may overlook specifics. Dimensions matter; will it fit in your space? The height can limit installation options. Also, assess maintenance requirements. An efficient lift with high upkeep is counterproductive. Rethink your choices and gather input from your team. Engaging them can uncover potential issues and lead to better decision-making.

| Model | Load Capacity (lbs) | Height (inches) | Energy Efficiency (kWh/year) | Speed (items/hour) |

|---|---|---|---|---|

| Model A | 1000 | 80 | 250 | 120 |

| Model B | 1200 | 72 | 230 | 140 |

| Model C | 1500 | 90 | 200 | 160 |

| Model D | 800 | 75 | 240 | 100 |

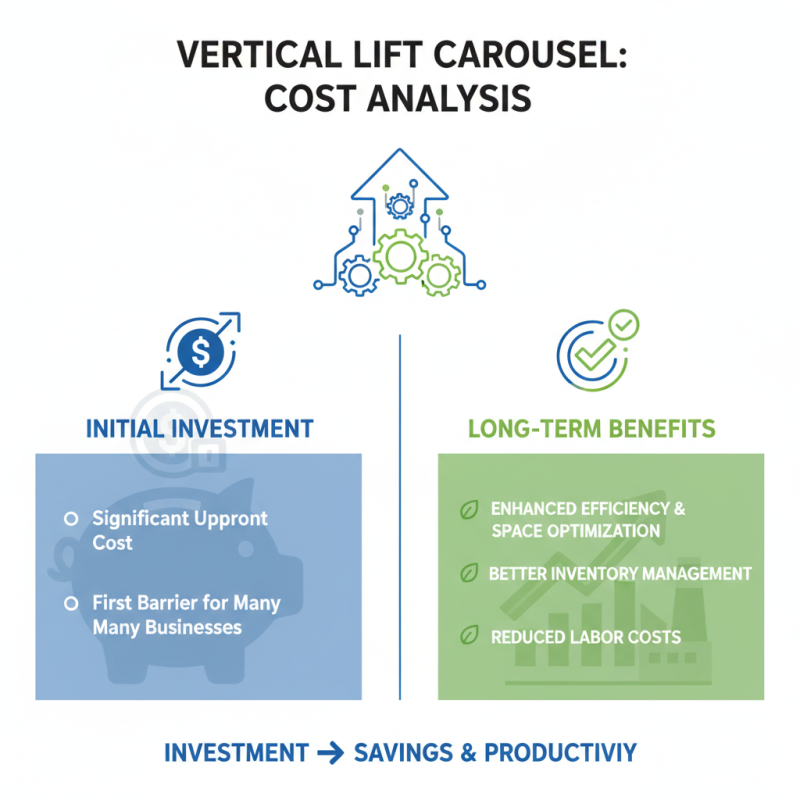

When selecting a vertical lift carousel, cost analysis is crucial. The initial investment can be significant. This is often the first barrier for many businesses. However, understanding the long-term benefits can change perspectives. Over time, these systems enhance efficiency and optimize space. This leads to better inventory management and reduced labor costs.

Consider the energy costs as well. A well-implemented system can save on operational expenses. However, less efficient models might drain resources. Evaluating maintenance needs is another step. Neglect can lead to increased costs down the line. Investing in the right option will minimize repairs and downtime.

In the long run, the return on investment can be substantial. Improved workflow means quicker retrieval of items. Employees spend less time searching, which boosts productivity. Yet, many businesses overlook this. They focus solely on upfront costs without recognizing future savings. A deeper dive into the total cost of ownership is essential for informed decision-making.

When selecting a vertical lift carousel, maintenance is crucial for longevity and performance. Regular upkeep prevents breakdowns and costly repairs. Checking components like belts and motors is vital. A routine inspection schedule can keep your system running smoothly.

Lubrication is often overlooked but essential. Proper lubrication reduces wear and tear. Pay attention to the loading and unloading areas. Excessive use can lead to dirt accumulation. This buildup may negatively affect performance over time.

Selecting the right materials can also impact maintenance needs. Durable materials can withstand heavy use, but it's important to assess their wearability. Sometimes, less durable options might seem appealing due to initial costs. However, they can lead to more frequent maintenance issues. Evaluate long-term implications before making a choice.