+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the ever-evolving landscape of logistics and supply chain management, an effective Warehouse Floor Plan is crucial for optimizing operational efficiency. According to a recent report by the Warehousing Education and Research Council (WERC), strategically designed warehouse layouts can lead to a productivity increase of 20% to 30%. As businesses strive to meet the growing demands of e-commerce, it is imperative to adopt innovative floor planning strategies that address not only space utilization but also workflow efficiency.

Moreover, the rise of automation technologies presents both challenges and opportunities for warehouse design. A study published by Logistics Management indicates that warehouses that integrate advanced robotics within their floor plans can achieve up to 50% faster order processing times. As we approach 2025, the need for a comprehensive and adaptable Warehouse Floor Plan will become even more critical, allowing facilities to accommodate the integration of new technologies while ensuring smooth operations and reduced overhead costs.

In light of these trends, creating a warehouse layout that is both functional and flexible will be essential for companies looking to maintain a competitive edge. A well-thought-out floor plan not only facilitates inventory management and order fulfillment but also enhances safety and employee productivity. As we delve into the essential elements of crafting an effective Warehouse Floor Plan for 2025, it is vital to consider both current industry data and emerging trends shaping the future of warehousing.

An efficient warehouse floor plan is crucial for optimizing operations and enhancing productivity in 2025. As the logistics landscape evolves, the traditional models of warehouse layout are becoming increasingly inadequate. A well-designed floor plan maximizes available space, improves workflow, and minimizes bottlenecks, which are essential for keeping pace with rising consumer expectations and the demands of e-commerce. By taking into account factors such as the flow of goods, access to technology, and employee safety, businesses can create an environment that supports seamless operations.

Moreover, the importance of an effective warehouse layout extends beyond immediate operational concerns. An optimized floor plan can lead to better inventory management, faster picking and packing times, and ultimately, improved customer satisfaction. As companies strive for greater agility and cost-effectiveness in their supply chains, the role of an efficient warehouse design becomes even more pronounced. In 2025, organizations must prioritize strategic planning and continuous evaluation of their floor layouts to accommodate evolving industry trends and technologies, ensuring they remain competitive in a rapidly changing market.

When designing an optimal warehouse layout, several key considerations must guide the planning process. First, understanding the flow of goods is crucial. This involves a careful analysis of how items are received, stored, and shipped. A well-structured layout minimizes unnecessary movement, reducing handling times and associated costs. By establishing distinct zones for receiving, storage, picking, and shipping, warehouses can enhance operational efficiency and ensure that inventory management is streamlined.

Another vital factor is the consideration of space utilization. Maximizing every square foot allows for more inventory without the need for additional storage facilities, which can become costly. This includes selecting appropriate shelving and racking systems that fit the specific dimensions of the warehouse. Vertical space should be utilized effectively, employing stackable designs to increase storage capacity. Additionally, incorporating technology such as automated systems can further enhance space efficiency by optimizing the way products are stored and retrieved.

Lastly, safety and accessibility should not be overlooked. Designing wide aisles and clear pathways ensures that both employees and equipment can navigate the warehouse freely, minimizing the risk of accidents. Adequate lighting and signage are also essential for maintaining a safe environment. By prioritizing these elements in the design process, a warehouse can not only boost efficiency but also create a safer workplace for its employees.

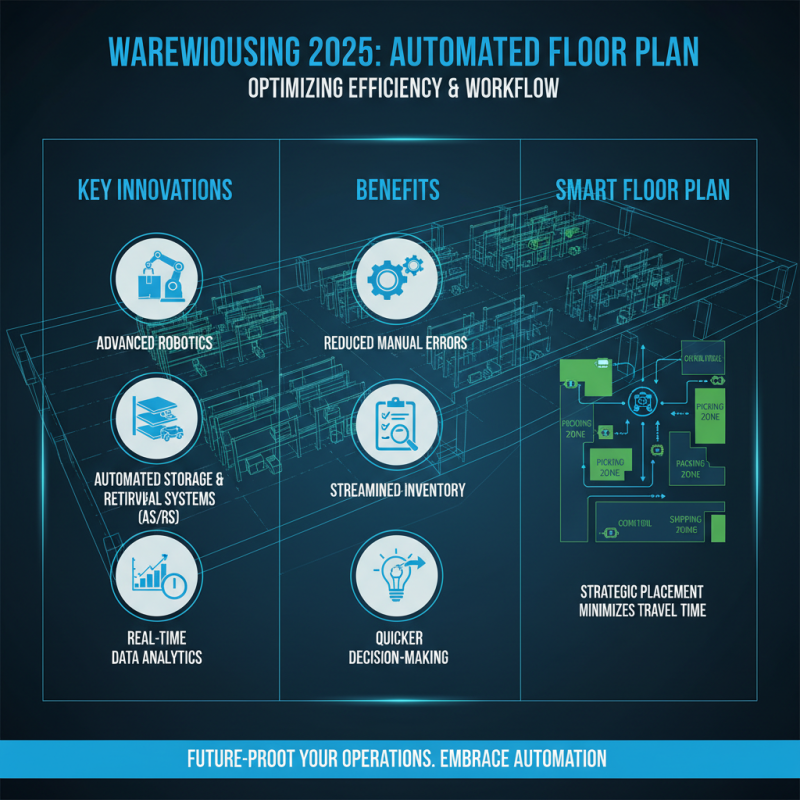

In the rapidly evolving landscape of warehousing, the incorporation of technology and automation into floor plans has become essential for optimizing efficiency. As we move into 2025, warehouses must embrace innovations such as advanced robotics, automated storage and retrieval systems, and real-time data analytics. These technologies facilitate seamless operations by reducing manual errors, streamlining inventory management, and enabling quicker decision-making. An effective floor plan will prioritize the strategic placement of automated systems to minimize travel time and improve workflow, ensuring that all areas of the warehouse are accessible and functional.

Additionally, the integration of smart technologies such as IoT sensors and RFID tracking can enhance visibility throughout the warehouse. These tools provide real-time insights into inventory levels and equipment status, allowing for proactive management of resources. By designing a floor plan that accommodates these technologies, warehouse managers can create a responsive environment that adapts to fluctuating demands. Utilizing digital twins and simulation tools during the planning phase can help visualize the impact of automation and technological integration, enabling better predictions of operational efficiency and productivity outcomes.

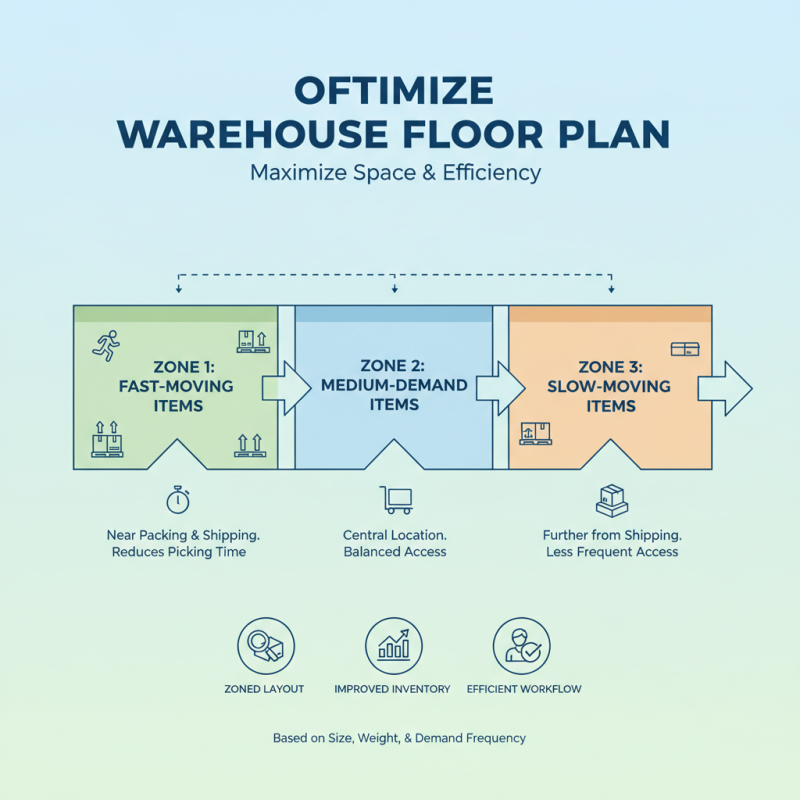

Creating an effective warehouse floor plan is essential for maximizing space utilization and enhancing inventory management. One best practice is to adopt a zoned layout that categorizes products based on their size, weight, and demand frequency. This strategy not only minimizes the time spent locating items but also streamlines the picking process. High-demand items should be placed closer to packing and shipping areas, while slow-moving items can be stored further away, allowing for a more efficient workflow and reducing unnecessary movement for warehouse staff.

Another critical aspect of a successful warehouse floor plan is the implementation of vertical storage solutions. Utilizing taller shelving units can significantly increase storage capacity without requiring additional floor space. Incorporating technology, such as automated storage and retrieval systems, can further optimize space by ensuring that items are stored and retrieved in the most efficient manner. Additionally, regular inventory audits and the use of inventory management software can help maintain accuracy and prevent overstocking or stockouts, facilitating a smoother operation that adapts to changing demands.

Evaluating and adjusting your warehouse plan is a continuous process that is essential for maintaining optimal efficiency. As business demands evolve, so should your warehouse layout. Regular assessments will help identify bottlenecks in workflows, underutilized spaces, and areas where technology can enhance productivity. By utilizing data analytics, warehouse managers can track performance metrics and make informed decisions regarding layout modifications, storage solutions, and inventory management practices. This proactive approach allows for agility in addressing dynamic business needs and optimizing resource use.

Furthermore, establishing a routine for reviewing your warehouse floor plan encourages ongoing improvement. Workshops, team meetings, and employee feedback can provide valuable insights into operational inefficiencies. Engaging warehouse staff in the evaluation process fosters a culture of continuous improvement and innovation. Adjustments to the layout should not only focus on immediate needs but also consider future scalability and versatility. By staying adaptable and regularly updating the warehouse design, businesses can ensure they are well-positioned to meet changing market demands and improve overall operational efficiency.