+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Optimizing warehouse operations is crucial for enhancing efficiency. Many businesses overlook key aspects that can lead to inefficiencies. It's not just about space; it's about workflow as well.

In modern warehousing, layout plays a significant role. A poorly designed layout can slow down operations. Think about how products are stored and retrieved. Every step in this process matters. If employees spend too much time searching for items, it impacts productivity.

Technology has transformed warehouse operations, but not all businesses adapt quickly. Automation can significantly reduce labor costs, yet some resist change. Emphasizing training is vital, as employees need to understand new systems. Reflecting on these challenges can lead to improved strategies. Ultimately, optimizing warehouse operations requires a balance of technology, training, and thoughtful layout design.

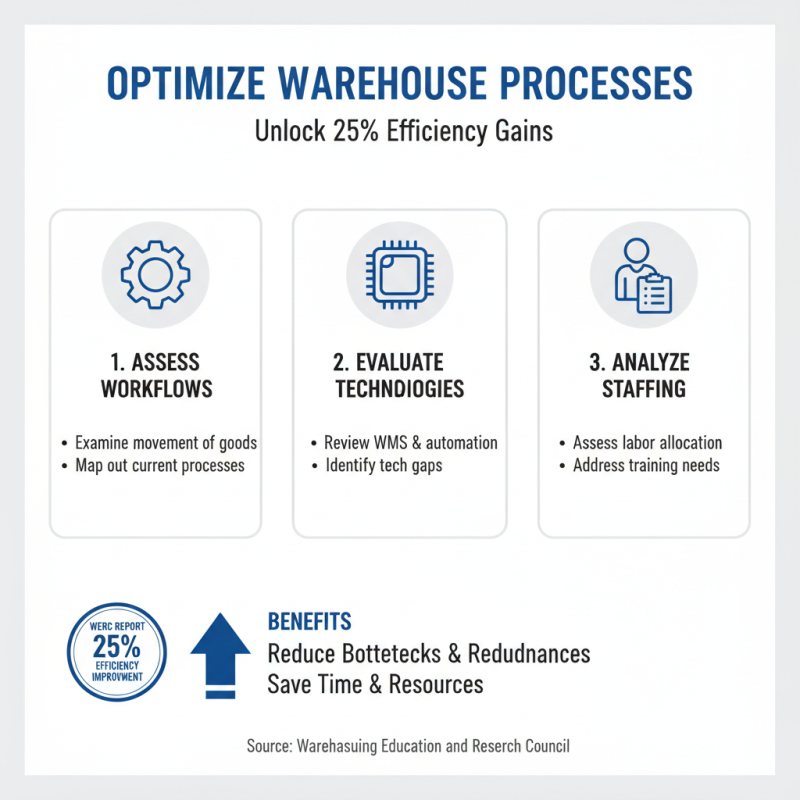

Assessing current warehouse processes is crucial for identifying improvement opportunities. A recent industry report from the Warehousing Education and Research Council (WERC) indicates that warehouses could improve efficiency by an average of 25% through better process assessment. This involves examining workflows, technologies, and staffing levels to pinpoint bottlenecks and redundancies. Many facilities overlook basic process evaluations, resulting in wasted resources and time.

Data also shows that 70% of warehouses report issues with inventory accuracy. These discrepancies often stem from ineffective checks and outdated systems. Addressing these problems can significantly boost productivity. Implementing regular audits and utilizing advanced inventory management systems can help. Adopting such systems has led to up to a 50% reduction in discrepancies in some cases. However, reliance on technology without training can lead to frustration and decreased morale among staff.

Moreover, not all warehouses prioritize employee feedback. Employees frequently have valuable insights into day-to-day operations. Survey data suggests that 65% of workers feel their suggestions are ignored. Encouraging open communication fosters a culture of continuous improvement. Warehouses should actively seek input from their teams to drive changes. Small adjustments based on employee feedback can lead to larger efficiency gains over time.

Implementing Advanced Warehouse Management Systems (WMS) can significantly enhance warehouse efficiency. According to recent industry reports, companies adopting WMS experience up to a 20% increase in operational productivity. This improvement comes from better inventory management and streamlined processes. By automating routine tasks, WMS reduces human error and labor costs.

Data integration is crucial. A fully integrated WMS connects all aspects of warehouse operations. This includes inventory tracking, order processing, and shipping logistics. A study showed that 70% of warehouses without advanced systems struggle with accuracy. This leads to delays and dissatisfied customers. Additionally, embracing automated systems may seem costly initially, but the long-term savings often outweigh these expenses.

Investing in training for staff is vital. Employees need to feel comfortable with new technologies. Resistance to change can hinder WMS effectiveness. Some warehouses report that 30% of their staff struggled during the transition. Continuous support and feedback are essential to address these issues. Inadequate training can lead to lower efficiency and wasted resources.

Streamlining inventory management is essential for optimizing warehouse operations. Efficient inventory control can reduce costs by up to 30%, according to industry research. Accurate tracking of stock levels ensures that resources are allocated effectively. Companies that implement real-time inventory systems see a significant decrease in stockouts and overstock situations.

Tips: Utilize barcode scanning for easier tracking. This reduces human error and enhances accuracy in inventory counts. Additionally, categorize inventory based on demand. This helps in prioritizing the most frequently accessed items, which can improve picking efficiency.

Investing in automation tools can yield considerable benefits. Reports show that warehouses that adopt automated inventory systems improve their order accuracy by 25%. However, it’s crucial to assess the actual needs of your warehouse before going all-in on automation. Not every warehouse may need the same level of technological integration. Sustainability must also be a consideration; evaluating the environmental impact of warehouse operations is becoming increasingly important.

Training and technology are essential for optimizing warehouse operations. A recent industry report indicates that companies investing in workforce training see a 25% boost in productivity. This increase often stems from a better understanding of equipment and workflow processes. When employees are well-trained, they can handle tasks more efficiently, leading to faster order fulfillment.

Incorporating technology can further enhance productivity. Automated systems streamline processes and reduce the possibility of human error. However, the integration of new technology also poses challenges. Workers may struggle with adapting to new systems. A survey found that 40% of employees expressed concerns about inadequate training for new technology. This gap highlights the need for ongoing educational programs.

Regular training sessions help employees become more comfortable with advanced tools. Data shows that 70% of employees felt more confident in their roles after receiving comprehensive training. On the other hand, without proper training, mistakes can lead to delays. Reflections on past implementations reveal that overlooking workforce training can hinder progress. Balancing technology adoption and employee education is critical for maximizing warehouse efficiency.

Optimizing warehouse layout is crucial for enhancing flow and maximizing space utilization. A well-designed layout reduces travel time and improves picking efficiency. According to a 2022 report by the Warehousing Education and Research Council, up to 30% of operational costs can be attributed to inefficient layout designs. This statistic underscores the importance of evaluating current layouts.

Integrating best practices is vital. Designate specific areas for receiving, storage, and shipping. Use vertical space effectively by implementing shelving systems. Many warehouses often neglect vertical storage, limiting their capacity. In fact, optimizing vertical storage can increase capacity by 20%.

While optimizing layouts, it’s important to reassess workflow regularly. Keep in mind that changes in product lines or order volumes can make initial designs obsolete. A 2023 survey revealed that 40% of warehouses had outdated designs that hindered performance. Continuous evaluation and adaptation are essential, but not always prioritized. This oversight can lead to unnecessary bottlenecks and extended operating times.