+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

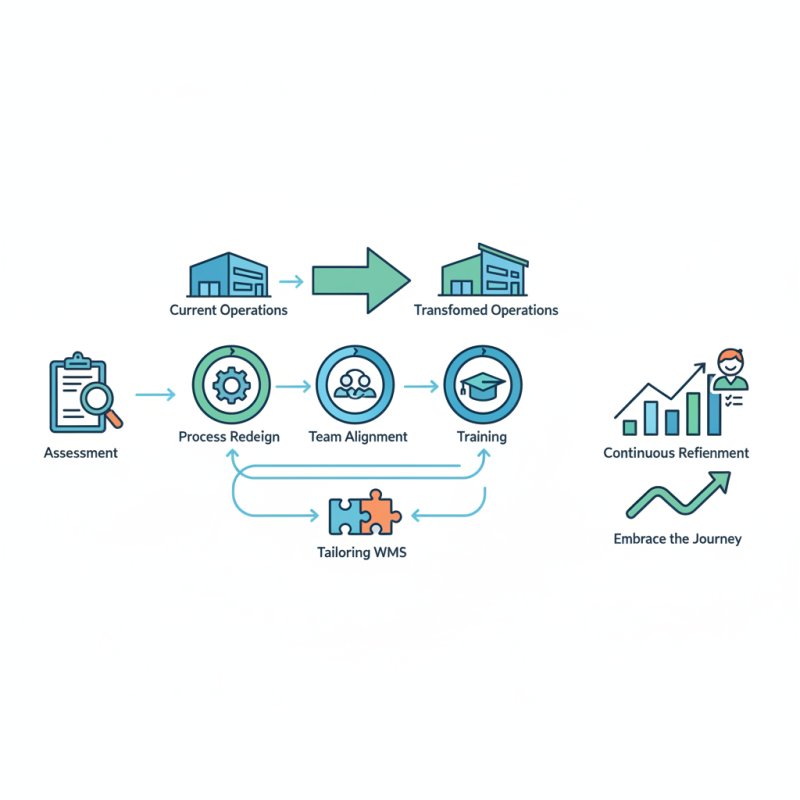

Implementing a Warehouse Management System (WMS) can transform your warehouse operations. Many businesses face challenges during WMS implementation. It's essential to plan carefully to avoid common pitfalls.

In a typical scenario, a warehouse operator may underestimate the complexity of this process. A successful WMS implementation requires more than just technology. It demands training, process redesign, and team alignment. Without these, the system may not perform as expected. Employees may struggle to adapt, leading to frustration and inefficiency.

Assessing your current processes before WMS implementation is vital. Identify gaps and opportunities for improvement. Engage your team early in the process. Their insights can guide you and reduce resistance. Remember, each warehouse is unique. Tailoring the WMS to fit your specific needs is crucial. Failing to do so can result in wasted resources and time. Embrace the journey, remain flexible, and continuously refine your approach.

Warehouse Management Systems (WMS) have revolutionized supply chain operations. They streamline processes, enhance inventory accuracy, and reduce operational costs. According to a report by Gartner, implementing WMS can lead to a 25% increase in order fulfillment accuracy. This accuracy is crucial for maintaining customer satisfaction and loyalty.

With WMS, real-time tracking of stock levels and orders becomes possible. This visibility helps prevent stockouts or overstock situations. However, many companies still struggle with integration. A study by Research and Markets revealed that 29% of organizations face challenges in integrating WMS with existing systems. Such difficulties can slow down the overall efficiency of warehouse operations.

WMS also enables data analysis that drives informed decisions. Businesses can identify trends and make proactive adjustments. Yet, not all implementations yield immediate improvements. A lack of proper training may impede the system's effectiveness. Employees must understand how to use WMS fully. Investing time and resources in training is essential for maximizing benefits.

Assessing your warehouse needs is a critical first step in successful WMS implementation.

Many businesses underestimate this process, leading to mismatched systems and wasted resources.

According to a study by Gartner, 70% of warehouse transformations fail

due to inadequate needs assessment. Understanding your current workflows, inventory turnover rates, and employee feedback is essential.

When evaluating your needs, consider your storage capacity and picking accuracy.

Data from the Warehousing Education and Research Council shows that warehouses can increase efficiency by

up to 40% with the right system tailored to their specific requirements.

Are your existing processes too slow? Review your picking methods.

Tip:

Involve your team in this assessment.

They can provide insights into daily challenges that may be overlooked.

Regularly analyze key performance indicators (KPIs), like order fulfillment time.

This helps identify areas needing improvement. Ultimately, tailoring the WMS to fit your operations can transform your

warehouse into a highly efficient hub.

Tip:

Consider conducting a gap analysis.

This reveals the difference between your current state and your desired goals.

It can act as a roadmap for WMS features that will benefit your operation.

Each warehouse has unique needs, and ignoring them may lead to further operational struggles.

Choosing the right Warehouse Management System (WMS) is critical for effective warehouse operations. Industry reports indicate that 79% of top-performing companies use WMS to optimize their supply chains. This tool can minimize errors and boost productivity. However, not all WMS solutions fit every operation. Each warehouse has unique needs based on size, product type, and customer demands.

When selecting a WMS, start by assessing your current processes. Identify inefficiencies and technical gaps. A mismatch can lead to costly mistakes. For instance, a company reported a 30% increase in order accuracy after switching to a tailored WMS. It’s essential to involve key stakeholders for insights. Input from warehouse staff can be invaluable. They understand day-to-day challenges well.

Look for scalability. The chosen WMS should grow with your business. Studies show that 53% of warehouses face challenges as they expand. This can lead to a loss in sales opportunities. A modular approach allows you to add features as needed. Evaluate vendors based on user reviews. Experiencing a demo can also illuminate what works and what doesn’t. Remember, the best WMS is one that enhances productivity without overwhelming your operation.

| Step | Description | Key Considerations | Expected Benefits |

|---|---|---|---|

| 1 | Assess warehouse needs | Space, inventory types, and current inefficiencies | Tailored WMS solution |

| 2 | Research WMS options | Cloud-based vs. on-premise, scalability | Access to advanced features |

| 3 | Evaluate vendors | Reputation, support services, and integration capabilities | Reliable partnerships |

| 4 | Plan implementation timeline | Resources required and project milestones | Streamlined roll-out process |

| 5 | Train staff | User manuals and hands-on training | Improved user competence |

| 6 | Monitor and optimize | KPIs to measure success | Continuous improvement and savings |

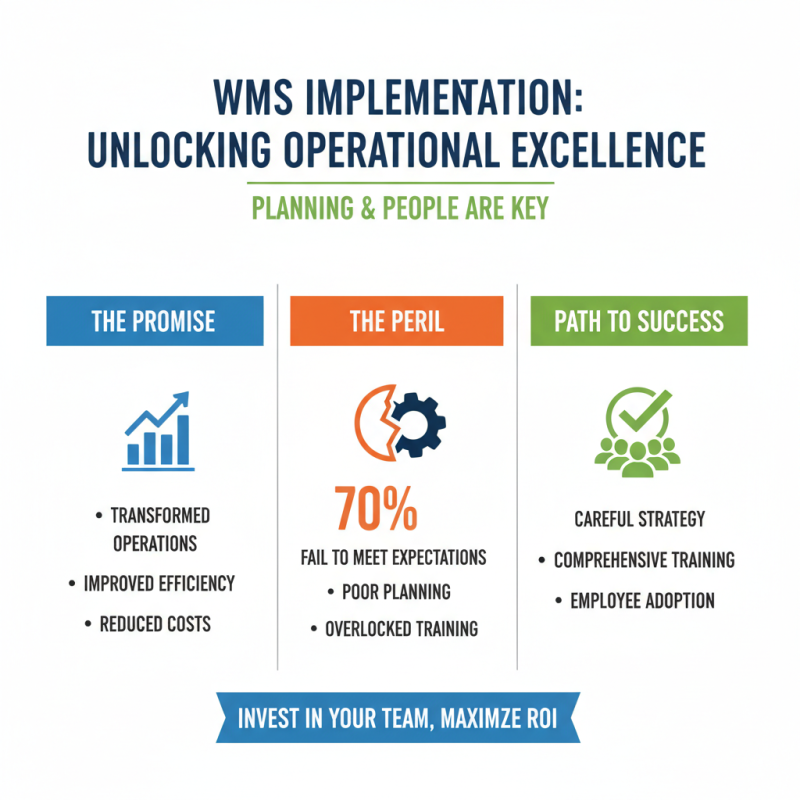

Implementing a Warehouse Management System (WMS) can transform operations. However, success requires careful planning. According to industry reports, 70% of WMS implementations fail to meet initial expectations. Many companies overlook user training. Employees need to understand the system for it to work effectively.

Focusing on data accuracy is crucial. A report by the Logistics Management Institute states that inaccurate inventory data can lead to a 30% increase in operational costs. Ensuring real-time updates is necessary. Without accurate data, decision-making becomes difficult, leading to customer dissatisfaction.

Integration with existing systems also poses challenges. Often, companies find their legacy systems incompatible with new software. This mismatch can cause delays, frustrating employees and customers alike. Regular communication among teams can help. Frequent check-ins can provide insights and address potential issues early on.

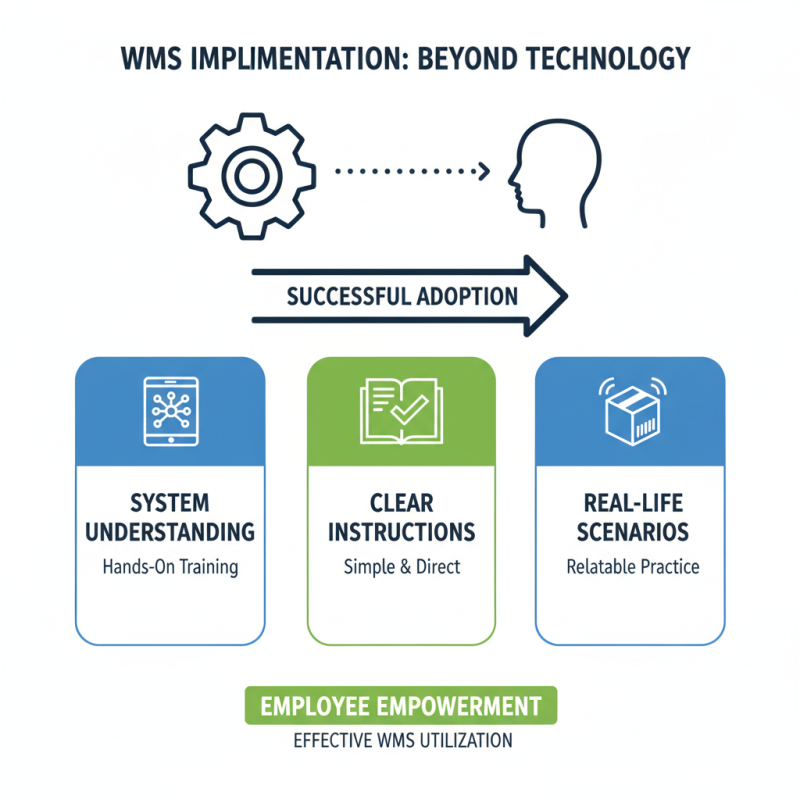

Implementing a Warehouse Management System (WMS) is not just about technology. Training is a vital part of the process. Employees need to understand the system fully to use it effectively. This is where hands-on training comes in. Simple, clear instructions are key. Offering real-life scenarios helps make the system relatable.

Change management is equally important. Resistance to change is normal. Some employees may be skeptical of new systems. Addressing their concerns should be a priority. Open forums for discussion encourage feedback. Listening helps build trust. Sometimes training sessions might miss the mark. It's essential to adapt based on employee needs.

Regular follow-ups are necessary after initial training. This can uncover gaps in knowledge. Recurrent training sessions keep skills sharp. Observing how employees interact with the WMS helps pinpoint areas for improvement. A continuous learning environment fosters adaptability. Mistakes will happen, and that’s okay. Each misstep is an opportunity to learn and grow.