+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

As businesses continue to evolve in the digital age, the significance of effective Storage Inventory management cannot be overstated. The way companies store, track, and utilize their inventory directly impacts operational efficiency and profitability. In 2025, the landscape of Storage Inventory solutions is poised for transformation, driven by advancements in technology and changing consumer demands. Companies must adapt to these developments to maintain a competitive edge.

In this discussion, we will explore the top Storage Inventory solutions that promise to optimize business operations in the coming year. From automated tracking systems to data analytics, these innovations can streamline inventory processes, reduce costs, and enhance decision-making. As we delve into the various options available, it will be crucial for businesses to understand how integrating these Storage Inventory solutions can lead to improved efficiency and productivity. By investing in the right systems, organizations can ensure that they remain agile and responsive in a fast-paced market, ultimately driving growth and success in 2025 and beyond.

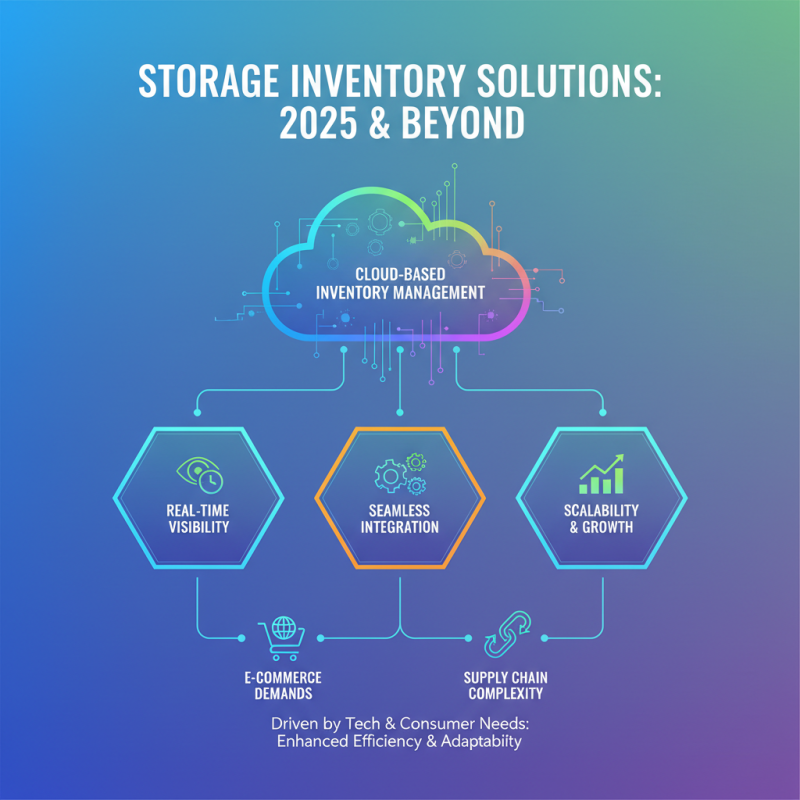

As we look forward to 2025, the landscape of storage inventory solutions continues to evolve, driven by technological advancements and changing consumer needs. Businesses are increasingly adopting cloud-based inventory management systems, which provide real-time visibility and enable seamless integration with other enterprise applications. This shift not only enhances efficiency but also allows for better scalability, catering to the growing demands of e-commerce and supply chain complexity.

**Tip:** When considering cloud solutions, prioritize systems that offer robust data analytics capabilities. These tools help monitor trends, optimize stock levels, and forecast demand more accurately.

Furthermore, automation and AI are playing crucial roles in transforming how organizations manage their storage inventory. Smart algorithms readily analyze data to optimize stock replenishment, reducing the risk of both overstock and stockouts. Robotics in warehouses enhances picking accuracy and speed, playing a significant part in fulfilling customer orders swiftly.

**Tip:** Evaluate the potential of AI-powered tools that can predict inventory needs based on historical data and current market trends—this can significantly enhance decision-making processes for your business.

The rise of sustainability in inventory management is another trend to watch. Companies are focusing on reducing waste and improving resource efficiency, ensuring that their storage practices align with environmental goals. Emphasizing eco-friendly solutions not only helps in compliance with regulations but also appeals to the growing base of environmentally conscious consumers.

**Tip:** Integrate recycling and waste management strategies into your inventory practices to promote sustainable growth while improving your brand image.

In 2025, businesses seeking to optimize their storage inventory will leverage key technology innovations that enhance efficiency and streamline operations. One of the pivotal advancements is the integration of artificial intelligence (AI) and machine learning into inventory management systems. These technologies enable real-time data analysis, allowing companies to predict stock levels, optimize shelf space, and automate reordering processes. By adopting AI-powered solutions, businesses can minimize human error and significantly reduce the time spent on inventory tasks.

Another essential innovation is the incorporation of Internet of Things (IoT) devices to facilitate smarter warehousing. With IoT sensors, businesses can track inventory movement throughout the supply chain, providing precise visibility of stock levels and location. This technology can also help in monitoring environmental conditions, ensuring that stored items remain in optimal conditions. As a result, companies can proactively address issues that might affect product quality or availability.

Tips: Implementing these technologies involves a careful assessment of existing systems. Start by identifying areas where efficiency can be improved and consider pilot programs to test new solutions. Additionally, providing training for staff on these technologies will maximize their effectiveness and ensure smooth adoption. Always stay updated on emerging trends to adapt your strategies accordingly and maintain a competitive edge.

| Technology Innovation | Description | Benefits | Implementation Timeline |

|---|---|---|---|

| Cloud-Based Inventory Management | Utilizing cloud technology for real-time inventory tracking. | Increased accessibility and reduced costs. | Q1 2025 |

| AI-Powered Demand Forecasting | Leveraging AI to predict inventory needs based on historical data. | Improved accuracy in stock levels and minimized waste. | Q2 2025 |

| Automated Picking Systems | Using robots to automate the picking of inventory. | Increased efficiency and reduced labor costs. | Q3 2025 |

| Internet of Things (IoT) Integration | Connecting inventory systems through IoT devices for real-time monitoring. | Enhanced tracking and data collection. | Q4 2025 |

| Blockchain for Transparency | Using blockchain technology to ensure transparency in the supply chain. | Increased trust and security in transactions. | End of 2025 |

The landscape of inventory management is rapidly evolving, driven largely by advancements in artificial intelligence (AI) and automation. As we approach 2025, businesses that wish to remain competitive must adapt their inventory management systems to incorporate these technologies. AI enables more accurate demand forecasting by analyzing vast amounts of data, thus helping businesses to maintain optimal inventory levels and reduce excess stock.

Tips: To leverage AI effectively, consider investing in platforms that offer predictive analytics. These tools can provide insights into purchasing patterns and seasonal trends, allowing you to make more informed inventory decisions.

In addition to AI, automation can streamline numerous processes in inventory management, such as order fulfillment and stock monitoring. Automated systems can track inventory levels in real-time, providing notifications when stock is running low and ensuring timely restocking. This not only enhances efficiency but also minimizes human errors that can lead to delays and increased costs.

Tips: When implementing automation, start small by automating key repetitive tasks like inventory counts or reorder alerts. Gradually expand the scope of automation as you become more familiar with its benefits and capabilities. This step-by-step approach will help minimize disruption while maximizing the overall impact on your business operations.

In today’s fast-paced business environment, leveraging data-driven decision-making is essential for optimizing inventory management. By implementing advanced analytics, companies can gain valuable insights into inventory levels, turnover rates, and customer demand patterns. This information enables them to make informed decisions that enhance operational efficiency and reduce costs. Inventory optimization driven by data analytics not only ensures that businesses can meet customer needs promptly but also helps in mitigating the risks of overstocking and stockouts.

Tips: To effectively utilize analytics in inventory optimization, start by establishing clear metrics that align with your business objectives. Regularly monitor these metrics through dashboards that provide real-time insights into performance. Additionally, invest in training your team to interpret data and implement strategic adjustments based on findings. Emphasizing a culture of data-driven decision-making across departments can foster collaborative efforts in improving inventory strategies.

Another critical aspect of data analytics is predictive modeling, which can forecast future inventory needs based on historical sales data. By anticipating demand fluctuations, businesses can adjust their inventory levels to align with market trends, ensuring optimal stock availability. Implementing automation in this process can further streamline operations and enhance accuracy in inventory management.

As businesses increasingly prioritize sustainability, the implementation of eco-friendly storage solutions has become crucial. According to a recent report by the World Economic Forum, implementing sustainable practices can reduce operational costs by up to 20% for logistics-based companies. For instance, optimizing inventory storage methods not only minimizes waste but also maximizes space efficiency, thereby aligning with green practices. Companies are adopting multi-tier racking systems and modular shelving solutions that enhance storage density while using recycled materials, significantly lowering their carbon footprint.

Moreover, organizations are leveraging technology to improve efficiency and reduce waste in inventory management. A study by Gartner indicates that businesses that utilize AI and machine learning for inventory optimization can decrease excess stock by as much as 30%. This not only conserves resources but also minimizes the environmental impact associated with the production and disposal of surplus goods. By integrating real-time data analytics into their storage solutions, companies can better forecast inventory needs and reduce overproduction, making strides toward a more sustainable operational model. In 2025, those who embrace these eco-friendly innovations will not only meet consumer demand for sustainability but also achieve significant cost savings and operational efficiencies.