+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

Effective warehouse stock control is essential for businesses looking to optimize their inventory management processes. In today's fast-paced and highly competitive market, proper inventory control not only helps in reducing holding costs but also enhances service levels by ensuring that products are available when needed. This article delves into the top 10 strategies that can significantly improve warehouse stock control, allowing organizations to streamline their operations and achieve greater efficiency.

Understanding the various warehouse stock control strategies is crucial for managing inventory effectively. From implementing robust tracking systems to leveraging data analytics for informed decision-making, these strategies can help identify inefficiencies and provide actionable insights. As we explore these key techniques, businesses can better navigate the complexities of inventory management and ultimately drive improved profitability. By adopting a systematic approach to warehouse stock control, companies can enhance their overall supply chain performance, ensuring that they remain competitive in an ever-evolving marketplace.

Effective warehouse stock control is essential for optimizing inventory management, ensuring that businesses can meet customer demand without overstocking or running into shortages. One key principle is implementing a robust inventory tracking system that allows real-time monitoring of stock levels. This helps in quickly identifying slow-moving items and enables informed decision-making regarding restocking and promotions.

Tips: Regularly conducting physical inventory counts is another fundamental practice. This can uncover discrepancies between recorded and actual stock levels, helping to maintain accuracy and prevent potential losses. Using cycle counting, where a certain percentage of inventory is counted regularly, can reduce the disruption caused by full-scale audits.

Additionally, leveraging technology such as Warehouse Management Systems (WMS) can significantly enhance stock control efficiency. These systems automate various processes, such as order picking and inventory tracking, leading to reduced human error and improved operational speed. Ensuring that all staff are trained to utilize these tools effectively can maximize their potential and contribute to a smoother inventory management process.

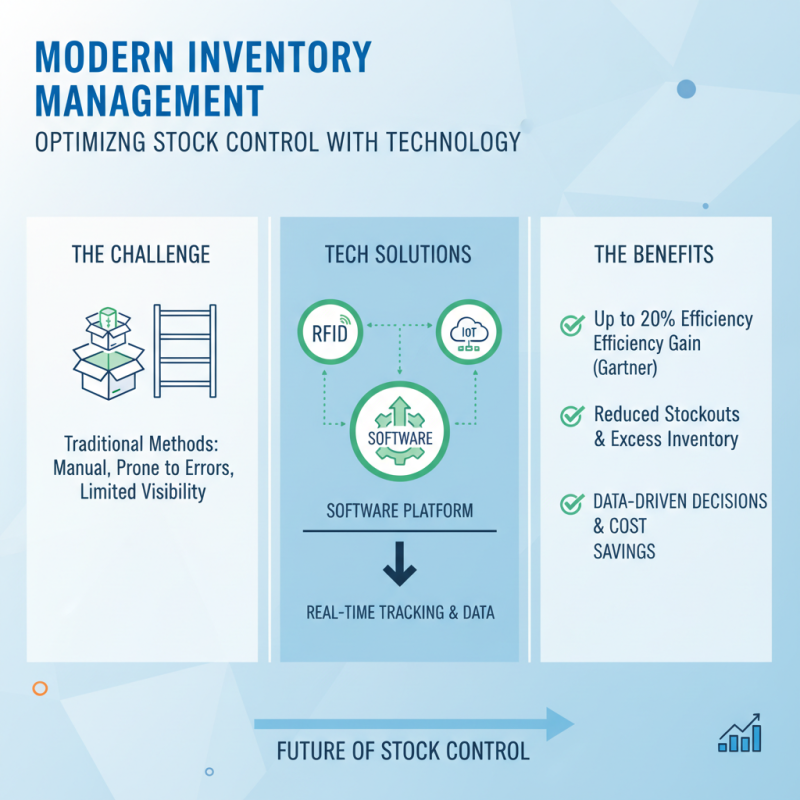

In the modern landscape of inventory management, leveraging technology is paramount for businesses aiming to optimize their warehouse stock control strategies. According to a report by Gartner, organizations that fully utilize inventory management software can improve their operational efficiency by up to 20%. Advanced technologies such as RFID (Radio Frequency Identification) and IoT (Internet of Things) have revolutionized traditional stock control methods, providing real-time visibility into inventory levels and movement. This enhanced transparency enables companies to make data-driven decisions, reduce stockouts, and minimize excess inventory, ultimately leading to cost savings.

Furthermore, automation tools such as automated picking systems and inventory management apps play a crucial role in streamlining warehouse operations. A study from the Warehousing Education and Research Council indicates that warehouses employing some form of automation experience a 35% increase in productivity. These technologies not only reduce human error but also allow for faster processing times, ensuring that businesses can meet customer demand promptly without compromising on service quality. Embracing these innovative solutions can significantly transform inventory management practices, allowing organizations to stay competitive in an increasingly fast-paced market.

Just-in-Time (JIT) inventory management is a strategic approach that minimizes excess inventory while ensuring that stock is available when needed. By synchronizing orders with production schedules, businesses can reduce holding costs and enhance efficiency. This method not only streamlines the supply chain but also helps in reducing waste, making it a cost-effective strategy for warehouse stock control.

Tips: One effective way to implement JIT is to strengthen relationships with suppliers. Establishing clear communication channels and setting up reliable delivery schedules ensures that materials arrive precisely when required, helping to avoid stockouts without needing to keep large inventories on hand. Additionally, employing demand forecasting tools can help predict inventory needs accurately, allowing you to adjust orders accordingly to match production demand.

Another essential tip is to invest in inventory management technology. Implementing software systems that provide real-time inventory tracking can enhance visibility across the entire supply chain. This technology allows businesses to quickly respond to changes in demand, thus maintaining optimal inventory levels and reducing the likelihood of excess stock or shortages. Through effective application of JIT strategies, businesses can achieve a more agile inventory system, ultimately leading to improved profitability and customer satisfaction.

Performing regular inventory audits and cycle counts is crucial for maintaining accurate stock levels and ensuring efficient warehouse management. An inventory audit involves a comprehensive review of all items stored in the warehouse, which helps to identify discrepancies between recorded and actual inventory. This process typically occurs at set intervals, whether quarterly or annually, and includes a thorough reconciliation of inventory records. It allows businesses to uncover issues such as theft, discrepancies, or errors in data entry that could otherwise lead to costly stock shortages or overages.

Cycle counts, on the other hand, are an ongoing process where a portion of the inventory is counted on a rotating schedule throughout the year. This method is beneficial as it minimizes disruptions to warehouse operations, allowing for continuous inventory accuracy without requiring a complete shutdown. By focusing on high-turnover or high-value items more frequently, businesses can quickly address any discrepancies and adjust their inventory records accordingly. Both practices, when implemented effectively, foster a culture of accuracy and accountability within the warehouse, ultimately leading to optimized inventory management and improved operational efficiency.

This bar chart illustrates the top 10 stock control strategies used in warehouse management to optimize inventory levels. Each strategy is measured based on its effectiveness rating, showcasing how companies prioritize their inventory management practices.

Effective inventory management is essential for maintaining optimal stock levels and minimizing costs. Stockouts can lead to lost sales and damaged customer relationships, while overstocks result in increased holding costs and waste. According to a report from the Council of Supply Chain Management Professionals (CSCMP), companies can incur costs amounting to 20-30% of the total inventory value due to stockouts. To mitigate these issues, implementing advanced demand forecasting techniques is crucial. These techniques leverage historical sales data, seasonality, and market trends to predict future demand more accurately, helping businesses maintain the right inventory levels.

Additionally, employing just-in-time (JIT) inventory practices can further reduce stockouts and overstocks. JIT minimizes the amount of inventory on hand by ensuring that materials arrive just as they are needed in the production process. As highlighted by a recent study from the Warehousing Education and Research Council (WERC), companies that adopted JIT strategies reported up to a 23% reduction in inventory costs. Furthermore, integrating inventory management systems that provide real-time data can enhance visibility across the supply chain, allowing for faster responses to demand fluctuations. Implementing these strategies not only streamlines operations but also leads to improved customer satisfaction and overall business performance.