+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In the fast-paced world of logistics, effective Warehouse WHS (Workplace Health and Safety) strategies are essential. A recent report by the Warehouse Safety Institute highlights that 85% of warehouse incidents can be prevented through proper practices. This statistic emphasizes the need for proactive measures in various operations.

John Smith, a leading expert in warehouse safety, states, "A safe warehouse is a productive warehouse." His insights underline the correlation between safety protocols and operational efficiency. When employees feel safe, they perform better.

However, many warehouses still face challenges. Inefficient layout designs and outdated equipment can hinder safety and workflow. A focus on continuous improvement is crucial. The industry needs to reflect on its practices regularly. Implementing innovative WHS solutions is not just beneficial; it’s necessary for future growth and safety in the Warehouse WHS sector.

Warehouse safety and efficiency are vital for smooth operations. Implementing effective WHS (Work Health and Safety) strategies can mitigate risks and enhance productivity. Regular training sessions are essential. Staff should know safety procedures inside out. Practical drills can reveal gaps in knowledge. This will encourage a culture of safety awareness.

Consider a more organized layout. A cluttered space increases the chances of accidents. Ensure clear pathways for movement. Use visual cues to signify danger zones. These details help in maintaining a safe environment. Regular checks can highlight potential hazards. It's important to act promptly and address any identified dangers.

Evaluate safety equipment frequently. Gear that isn’t up to standard can compromise worker safety. Establish a routine for inspections. Keeping equipment updated is a continual process. Encourage employees to report issues. Sometimes, staff miss the bigger picture. Open discussions can help identify unseen risks and enhance overall safety protocols.

Workplace health and safety (WHS) in warehouses is crucial. According to the National Safety Council, over 100,000 injuries occur in warehouse settings annually. This highlights the urgent need for improved safety practices. A single injury can cost a company thousands in medical expenses and lost productivity. These figures demand immediate action.

Warehouses face unique hazards. Forklifts, heavy lifting, and narrow aisles increase risks. This environment leads to accidents if proper safety measures are not followed. A recent industry report shows that inadequate training contributes to over 30% of warehouse injuries. Many workers are unfamiliar with emergency procedures. This knowledge gap can have severe consequences.

Implementing strategies can enhance WHS. Regular training sessions are vital. Workers need clear, practical knowledge of their roles. Ensuring proper use of equipment is also key. Simple checks can prevent injuries. It's easy to overlook the basics, but continuous vigilance is necessary. In a fast-paced environment, even small lapses can lead to accidents. Uncovering these gaps is essential for fostering a safer workplace.

An effective Workplace Health and Safety (WHS) strategy enhances warehousing operations significantly. It starts with identifying hazards. Regular risk assessments keep safety at the forefront. Workers should report potential dangers without fear. This encourages a proactive safety culture. Safety training is vital. Engage employees with hands-on workshops. It reinforces safety protocols in a tangible way.

Moreover, proper equipment maintenance is crucial for safety. Broken or outdated machinery can lead to accidents. Setting up scheduled maintenance checklists can prevent failures. Visibility is also key in warehouses. Good lighting and clear signage reduce confusion and accidents. Regularly review workspace layouts to improve flow and reduce hazards.

It's important to engage employees in safety discussions. They often notice issues not visible to management. Feedback is essential for refining safety practices. However, not all strategies will work seamlessly. Some may need adjustments. If an approach fails, analyze the reasons. Adaptation is part of growth in safety management.

In warehouse operations, safety is paramount. Implementing effective training programs can significantly enhance workers’ safety awareness and skills. A study by the Occupational Safety and Health Administration (OSHA) found that proper training can reduce workplace injuries by 30%. These programs should focus on real scenarios, allowing employees to practice handling equipment and responding to emergencies.

Hands-on training is vital. Workers often learn best through doing. Simulation exercises help them understand potential hazards. A report by the National Safety Council indicates that organizations with regular training see a 50% decrease in accident rates. However, many companies fail to regularly update their training materials. This inconsistency can lead to gaps in knowledge, leaving employees vulnerable.

Feedback is crucial. Employees should feel comfortable sharing their concerns. This input can reveal areas of improvement. Unfortunately, not all organizations prioritize a culture of open communication. Training programs must not only teach skills but also foster an environment where safety is continuously discussed. Investing time in these strategies can yield better outcomes for operations and employee wellbeing.

In modern warehouses, leveraging technology is key to enhancing safety practices. Implementing real-time monitoring systems can reduce workplace accidents significantly. According to industry studies, technology can decrease incidents by up to 40%. This improvement stems from automated alerts that notify workers of unsafe conditions before accidents occur.

Wearable devices also play a crucial role. They track employee movements and provide data on potential hazards. A report shows that companies using wearables report a 30% increase in safety compliance. Such tools not only create awareness but also empower employees to take action regarding their safety.

Yet, the integration of technology isn't without its challenges. Many warehouses face issues with data integration and employee training. Some workers may resist using new devices or may misunderstand their functions. It's essential for management to address these concerns. Regular training sessions can help workers feel comfortable with new systems.

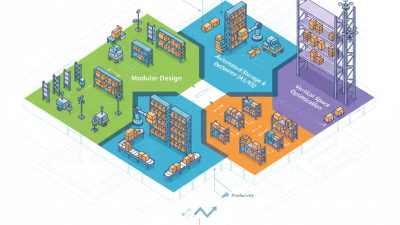

Effective Warehouse WHS (Workplace Health and Safety) strategies are crucial for ensuring both operational efficiency and employee safety in warehouse environments. Understanding the importance of WHS in warehouses means recognizing how safety directly impacts productivity and employee morale. Key components of an effective WHS strategy include comprehensive training programs to enhance safety awareness and skills among staff, which are vital for maintaining a safe working environment.

Additionally, leveraging technology can play a significant role in monitoring safety practices and identifying potential hazards. Regular safety audits and assessments are essential for continuous improvement, allowing warehouses to adapt their strategies and enhance safety measures proactively. By implementing these WHS strategies, warehouses can foster a culture of safety while optimizing operational effectiveness.