+8618862309186

+8618862309186

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In 2026, the demand for efficiency in warehouses continues to rise. A Vertical Carousel Module emerges as a pivotal solution. This innovative storage system optimizes space and enhances retrieval time.

Imagine a busy warehouse, cluttered with products. Employing a Vertical Carousel Module transforms this chaos into order. Items rotate vertically, bringing them to the picker’s access point. It saves space, boosts productivity, and minimizes labor costs. However, some might question the initial investment.

Efficiency often comes with a price tag, requiring careful consideration. While the benefits may seem clear, potential users must assess their specific needs. The value of a Vertical Carousel Module lies in its ability to adapt to various environments. Balancing costs against potential gains presents a challenge that requires reflection.

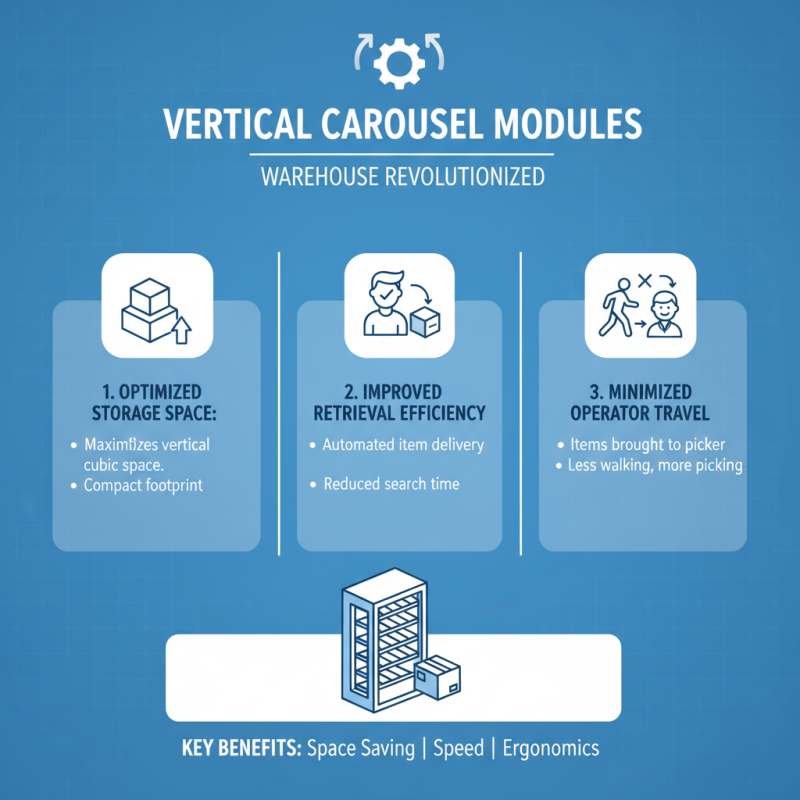

A Vertical Carousel Module is a type of automated storage system. It consists of vertically arranged carriers that rotate around a central axis. This design allows for efficient use of vertical space, reducing the footprint of storage operations. According to a recent industry report, up to 90% of warehouse space can be utilized more effectively with vertical carousels.

These modules provide rapid access to stored items. With retrieval times averaging 15-30 seconds, they enhance productivity significantly. Additionally, they reduce labor costs. By minimizing search and retrieval time, businesses can focus on core operations. However, the initial investment can be a barrier for some companies.

Tip: Evaluate your storage needs carefully. Consider conducting an analysis to determine if a vertical carousel fits your operational model. Sometimes, the investment does not yield immediate returns.

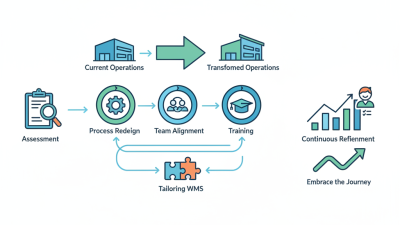

Mistakes can happen when implementing new technology. Staff may struggle to adapt to new processes. This is a critical area to address. Providing adequate training is essential for a smooth transition. Regular feedback can also help identify ongoing issues. Addressing these concerns will lead to improved workflows over time.

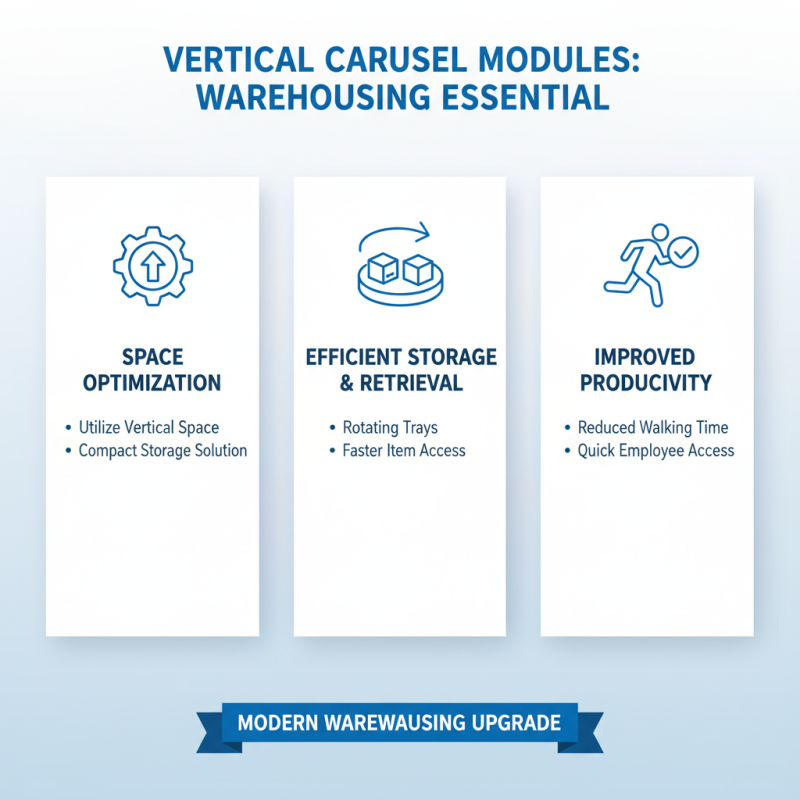

Vertical carousel modules are increasingly popular in various industries. These systems allow for efficient storage and retrieval of items in a compact space. Key features include rotating shelves that deliver items to operators. This design minimizes the time spent searching for products, leading to enhanced productivity.

Components of vertical carousels typically involve several essential parts. The storage bins are adjustable to fit various item sizes. Motors power the rotation, ensuring smooth movement. Sensors track inventory levels and provide real-time data. Reports from the Material Handling Industry (MHI) show that facilities using vertical carousels can reduce labor costs by up to 30%.

Despite their benefits, vertical carousels require regular maintenance. Over time, parts may wear out, leading to downtime. Some users note the initial cost might be a barrier. However, the investment often pays off through improved efficiency and reduced space requirements. Data suggests that modern vertical carousels can utilize 85% of vertical space, which is often underutilized in warehouses.

Vertical Carousel Modules are becoming essential in modern warehousing. These systems optimize space by using vertical space effectively. They replace traditional shelving units, providing a compact solution for inventory storage. Items are stored in rotating trays, making retrieval faster. Employees can quickly access products without excessive walking.

One major advantage is improved efficiency. Warehouses can reduce labor costs significantly. Workers spend less time searching for items. However, there can be a learning curve. New employees may require time to adapt to the system. Familiarity is important for maximizing productivity. Training is sometimes overlooked, leading to frustration.

Additionally, Vertical Carousel Modules enhance inventory management. They allow for real-time tracking of products. This reduces errors and minimizes overstock. However, the initial investment might pose a challenge. Smaller businesses may hesitate to adopt such technology. Balancing cost and benefit is crucial in decision-making processes. Overall, these modules present unique advantages for modern warehousing but require careful consideration.

Vertical Carousel Modules are revolutionizing warehouse operations. Their design optimizes storage space and improves item retrieval efficiency. These systems rotate to bring items closer to the operator, minimizing the need for extensive walking or searching.

In 2026, businesses benefit immensely from these modules. Efficiency climbs as retrieval times shrink significantly. Employees spend more time on important tasks and less on mundane ones. Improved organization leads to increased productivity. However, companies must also consider the learning curve associated with new technology. Staff training is crucial for maximizing potential.

Implementing Vertical Carousel Modules can pose challenges. Initial costs can be high, and maintenance requires attention. Not all items are suitable for this system, which may limit its application. Understanding the balance between innovation and practicality is essential for success.

In 2026, vertical carousel technology is poised to undergo significant advancements. These systems will likely incorporate artificial intelligence to enhance efficiency. Imagine a carousel that analyzes stock levels and predicts reordering needs. This means less downtime and streamlined operations in warehouses and retail spaces.

Another exciting trend involves sustainability. The manufacturing of vertical carousels may shift towards eco-friendly materials. This change could reduce the carbon footprint of these systems. Smart energy management could also be integrated. Energy-efficient motors and sensors will optimize power use, reducing operational costs.

Challenges remain. Companies might struggle to adopt these technologies due to high initial investments. The learning curve can be steep. Employees need training to maximize the benefits of these systems. Moreover, businesses must balance innovation with practicality. It’s essential to evaluate if such investments align with long-term objectives.